|

|

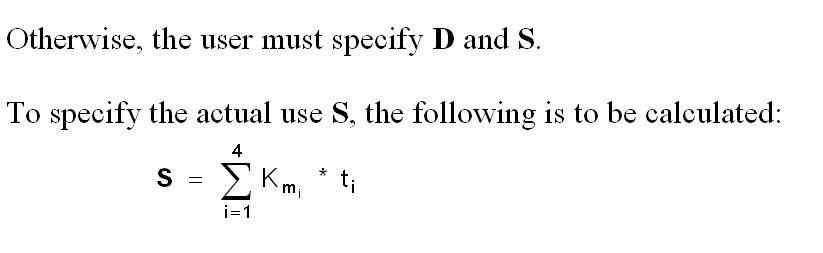

Subject: the theoretical potential of use Помогите, пожалуйста, найти правильный русский термин для "теоретического срока службы ????"Также интересует русский термин для " the actual requests of the gear" Заранее спасибо! Контекст: 1.2.3 General revisions: As set forth in the UNE 58919:1995 standard. “Numerous elements of the kinematic chain of a series hoisting gear are not visible and, consequently, they cannot be checked regularly following the prescribed controls. For that, an incipient breakage or failure can hardly be detected. As the time passes by, when the theoretical potential of use D, which the gear has been sized for has been elapsed, a hazard might appear with an increasing probability”. Thus, the theoretical potential of use D, in hours of lifetime which the machine has been designed for, allows by comparing with the actual requests of the gear S in hours, the Safe Operating Periods of Time PFS to be especified for each hoisting gear of the crane. For a crane to be whitin a safe operating period of time, the following is to be met : When the theoretical use of service D is reached or exceeded, that is, when S/D ≥1, a general revision is to be performed so as to be able to continue using the gear. This general revision is to be performed not later than 10 years from the first commissioning of the crane and, after that, 10 years later, as a maximum, after each general revision. The manufacturer or the company performing the general revision is to specify the value of the theoretical use D and the new deadline for the following general revision. The schedule of the Safe Operating Period of Time, PFS, is proposed in the section III-02.1.2.3 as a guidance so as to set up the interval between general revisions. This value is calculated as a quotient between two parameters: the actual request S or actual operating conditions of the gear and the theoretical potential of use D, in years. If the manufacturer provides the potential of use D of gears and these are equipped with recorders that record automatically the S value, the calculation of PFS is made immediately. Otherwise, the user must specify D and S. To specify the actual use S, the following is to be calculated: The sum is the resultant of weighing each one of the four loading levels specified by UNE 58915, represented by its parameter of the loading spectrum Kmi, by the time ti during which the crane has been handled by Table-1. The user is to record the operating conditions of the crane, at least, on the occasion of the yearly revision, applying one of the three methods (UNE 58919): 1. Using instrumentation providing the S value, The first method provides directly S, as already stated. The second method implies that the user assigns the time recorded by the counter for each loading level and performs the sum of products time recorded by Kmi value, which represents the loading level the time of which has been measured. The S result is to be increased by 10%, in order to take into account the possible inaccuracy of this method, to calculate the PFS. The third method implies that the user records the operating times for each level of the loading spectrum by estimation and calculates the sum of the corresponding products. The S value thus is increased by 20% to calculate the PFS. For the results obtained by the three methods for the exposed record of S to be acceptable, it is understood that: 1. All of the prescribed tests have been carried out for the hoisting gear. ++++++ |

|

Поскольку английский текст однозначно косой, привожу оригинал из документа: ++++++ 1.2.3 Revisiones generales: Como indica la norma UNE 58919:1995. “Numerosos elementos de la cadena cinemática de un aparato de elevación de serie no son visibles y por consiguiente no pueden verificarse regularmente con ocasión de los controles prescritos. Por ello, apenas se pueden detectar una rotura o una avería incipiente. A lo largo del tiempo, cuando el potencial teórico de utilización D, para el cual el mecanismo ha sido dimensionado se ha consumado, un peligro puede aparecer con una probabilidad creciente”. Así pues, el potencial de utilización teórico D, en horas de vida para el que ha sido diseñada la máquina, permite determinar, comparándolo con las solicitaciones reales del aparato S en horas, los Periodos de Funcionamiento Seguro, PFS para cada mecanismo de elevación de la grúa. Para que una grúa se encuentre en un periodo de funcionamiento seguro, debe cumplirse: Cuando se alcance o supere la utilización teórica de servicio D, es decir cuando S/D ≥1, se debe de realizar una revisión general para poder seguir utilizando el aparato. Esta revisión general debe efectuarse no más tarde de los 10 años desde la primera puesta en servicio de la grúa y posteriormente, a los 10 años, como máximo, después de cada revisión general. El fabricante o la empresa que realiza la revisión general, debe determinar el valor de la utilización teórica D y la nueva fecha límite para la siguiente revisión general. +++++++++ PERIODICIDAD DEL MANTENIMIENTO En el apartado III-02.1.2.3 se propone la determinación del Período de Funcionamiento Seguro, PFS, como indicativo para establecer el intervalo entre revisiones generales. Este valor se calcula como cociente entre dos parámetros: la solicitación real S o condiciones de funcionamiento reales del aparato y el potencial teórico de utilización D, en años. Si el fabricante facilita el potencial de utilización D de los mecanismos y estos están equipados con registradores que registren el valor de S de forma automática, el cálculo de PFS es inmediato. En caso contrario, el usuario debe determinar D y S. Para determinar la utilización real S, debe calcular: El sumatorio es la resultante de ponderar cada uno de los cuatro niveles de carga determinados por la UNE 58915, representado por su parámetro del espectro de carga Kmi, por el tiempo ti durante el que la grúa lo ha manejado Tabla-1. |

|

В контексте одна формулка пропущена, поскольку была картинкой. Добавляю сюда. Возможно, кто-то знает толковый материал на данную тему. Приму ссылку на него с благодарностью.

|

|

Расчетный срок службы. Существующие технические требования. |

|

Спасибо, но второе плохо вяжется с "в часах" Thus, the theoretical potential of use D, in hours of lifetime which the machine has been designed for, allows by comparing with the actual requests of the gear S in hours, the Safe Operating Periods of Time PFS to be especified for each hoisting gear of the crane. получается - .. расчетный срок службы Д (в часах) надо делить на существующие технические требования (в часах), для получения коэффициента.... |

| You need to be logged in to post in the forum |